Key Attributes of Aurora Microplates’ Plates

-

A1 Chamfer: Allows for quick visual orientation of microplates when setting up automation runs.

-

Bar Coding: Each label has an 8-digit number adjacent to the bar code symbol. It can be used for data collection and auditing of the scientific data on the microplate. Labels have been tested for readability, chemical resistance, and temperature variation.

-

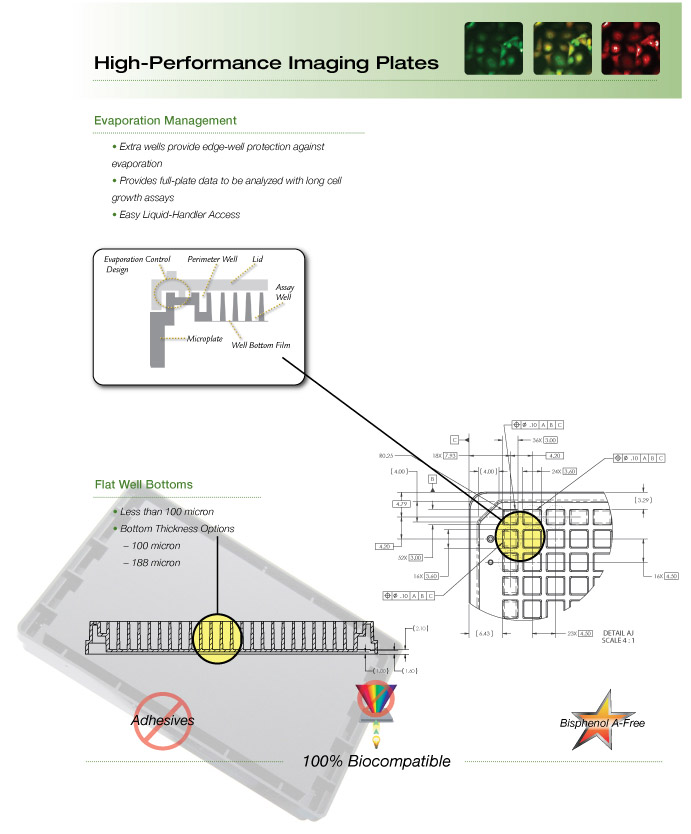

Well Arrays: Features an array of 1700 wells on the 1536-well microplates or 3700 wells on the 3456-well microplates, which includes assay wells and perimeter wells.

-

Perimeter Wells: The perimeter consists of 164 or244 dummy wells for the 1536-well and 3456-well microplates, respectively. When filled with aqueous or DMSO solutions, these wells effectively shield the assay wells from the edge effects of evaporation or water uptake.

-

Assay Wells: Featuring a 32 X 48 well array for the 1536-well microplates and a 48 X 72 well array for the 3456-well microplates. Both microplates are compatible with the 8 X 12 grid that is common in liquid handling and microplate reading devices.

Unique Features Increase Performance

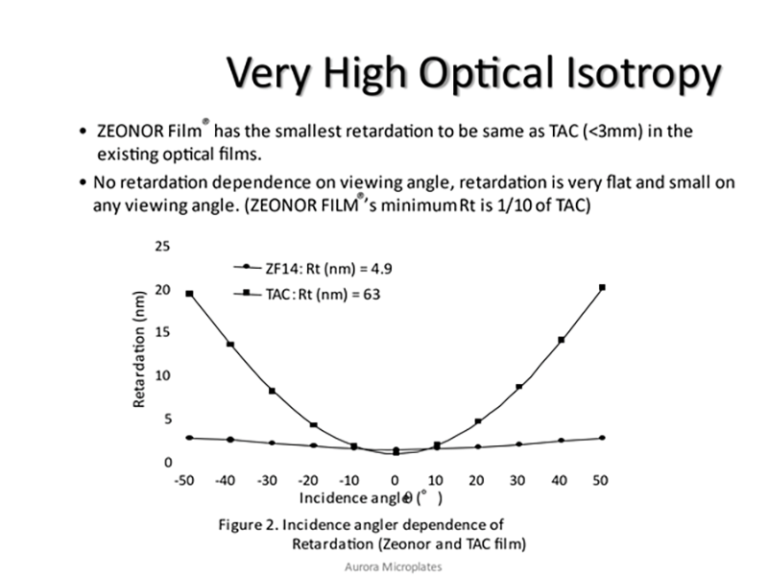

All Aurora film-bottom plates are made with 100% Virgin COP film that has extreme uniformity in thickness and optical clarity. All Aurora film bottom plates are made to pass light without distortion.