Our Products

All Aurora Microplate Products are made with 100% Cyclo-Olefin Polymer (COP) materials- for both the plate frame and the film-bottom materials. COP is 100% biocompatible, chemically inert, mechanically stable and optically transparent in a broad wavelength range.

Learn more about ZeonorFilm™https://www.zeon.co.jp/en/business/enterprise/plastic/film/

Attention CellTiter-Glo® Assay Users: White Paper

Key Attributes of Aurora Microplates’ Plates

-

A1 Chamfer: Allows for quick visual orientation of microplates when setting up automation runs.

-

Bar Coding: Each label has an 8-digit number adjacent to the bar code symbol. It can be used for data collection and auditing of the scientific data on the microplate. Labels have been tested for readability, chemical resistance, and temperature variation.

-

Well Arrays: Features an array of 1700 wells on the 1536-well microplates or 3700 wells on the 3456-well microplates, which includes assay wells and perimeter wells.

-

Perimeter Wells: The perimeter consists of 164 or244 dummy wells for the 1536-well and 3456-well microplates, respectively. When filled with aqueous or DMSO solutions, these wells effectively shield the assay wells from the edge effects of evaporation or water uptake.

-

Assay Wells: Featuring a 32 X 48 well array for the 1536-well microplates and a 48 X 72 well array for the 3456-well microplates. Both microplates are compatible with the 8 X 12 grid that is common in liquid handling and microplate reading devices.

Unique Features Increase Performance

High Light Transmittance:

All Aurora plates exhibit high transmittance of UV, visible, and near-IR wavelengths of light. This transmittance is superior to other plastics used in optic quantitation, including polystyrene, and results in improved research results. The plates support an expanded optical window down to 240nm. These disposable plates are well-suited for absorbance measurements of nucleic acid, and protein concentrations at 260nm and 280nmand provide a less expensive alternative to fragile glass-bottom plates.

Low Auto-Fluorescence:

COP has less than 1% the native auto-fluorescence of polystyrene when excited at UV wavelengths of light. The result for life-science researchers is better assay signal-to-noise performance and greater sensitivity.

Broad Chemical Resistance:

Our products are chemically inert to many standard laboratory organics including DMSO, for example. This enables the use of our plates for storage of chemical compound libraries in used in screening applications for drug discovery.

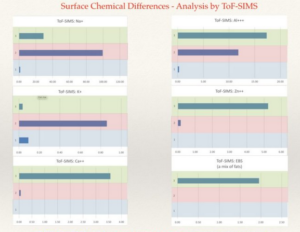

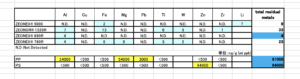

Biocompatibility/Chemically Inert:

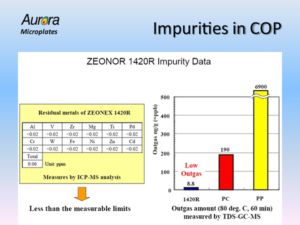

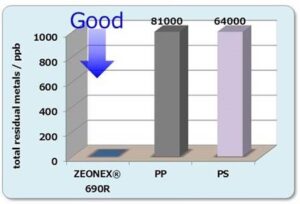

No catalysts or reactive intermediates are used during the polymerization process and manufacturing of our plates. This results in a very inert plate surface. Additionally, there are no heavy metals or oxidizers present to react with your compounds or biological materials.

Thermal Stability:

Our plates exhibit excellent mechanical memory from -80°C to +120°C. This wide range of stability is conducive to cold storage as well as thermal-cycling.

Rigidity for Mechanical Stability:

COP’s material hardness and a 2.2GPa rigidity resists microplate surface curvature by mechanical handling or heat treatments below 120°C. In addition, these plates will with-stand numerous repetitive heat-sealing applications, without deforming of the top surface-which is critical in Acoustic Dispensing Applications.